Aerospace applications impose many challenging conditions on the equipment such as acceleration during launch, effect of gravity as orbit is achieved, vibration, vacuum, and thermal variation. This causes continuous stress on the equipment.

The requirements of material for opto mechanical space applications are low thermal expansion, and to be dimensionally stable. Most solid materials expand when their temperature is increased however in space dimensional stability is essential, that is, how to control it and keep it within specific limits.

Aerospace Optical Mirror Mounts are used to mount optical mirrors in a stable stationary position in laser or optical systems.

To operate effectively the mount has to be ultra stable, exert low stress on the optics to minimize optical surface distortion, have high stiffness to maintain the optic alignment, maintain the specified tolerance in the operational temperature range, maintain the position of the optical element throughout its assigned life time, and have minimum mount size and weight.

Long term dimensional stability is required for support structures in many instruments having optical components like mirror mounts. For example, optical imaging systems on space flights such as the Saturn bound Cassini spacecraft impose very strict requirements on the optical mounts supporting the camera system. Not only must the material meet the dimensional stability requirements, it must also be machinable and have adequate mechanical strength.

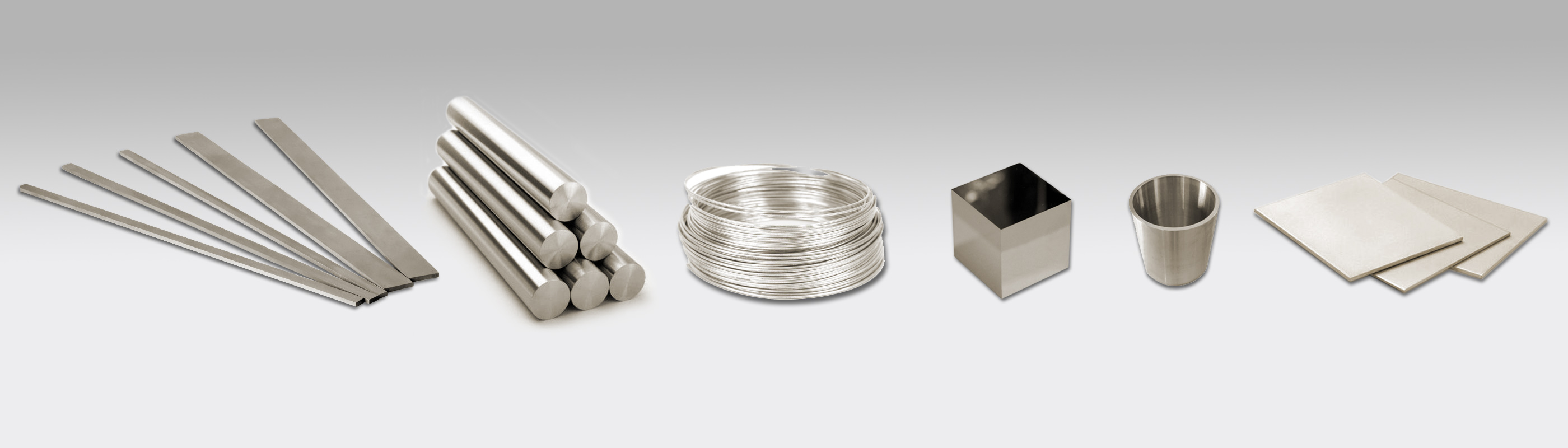

Invar 36 is a suitable and widely used material for space applications due to its low coefficient of thermal expansion (CTE), and because its mechanical and dimensional stability properties can be controlled and modified using specific heat treatment and cold working processes.

Some typical applications include lens and mirrors cells, interfacing spacers between optics and other structures, optical measuring equipment, metering rods for telescopes and laser cavity structures.