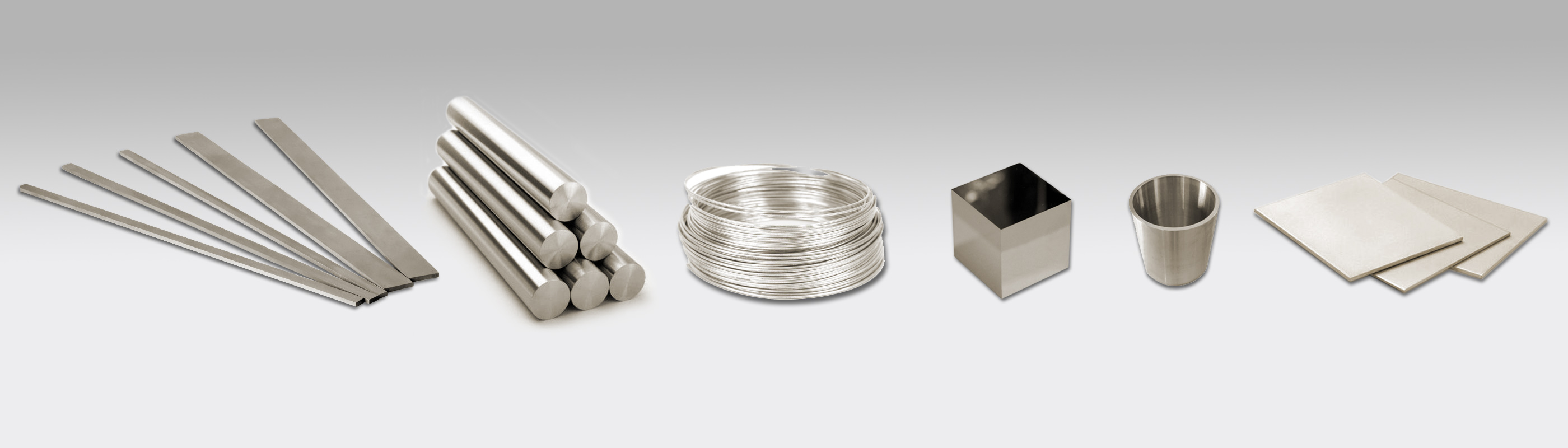

Pure Molybdenum is a silverish grey metal and one of the elements of the periodic table.

With a high melting point (4753°F) it has the ability to maintain its hardness and has a low rate of expansion at very high temperatures. It has excellent thermal conductivity, resistance to corrosion and wear, and high stiffness.

Molybdenum is a refractory metal that is often used as an alloying agent for stainless and structural steel to make super alloys. Its physical characteristics are very similar to chromium ( Cr) and tungsten (W).

Processed molybdenum is used primarily as an alloy to produce high strength structural steels in the construction industry (approximately 35%), around 25% is used to enhance the properties of stainless steels, the chemical industry uses around 14%, pure metal applications occupy 6%, formation of superalloys 5%, cast iron 6%, tool and high speed steels around 9%.

Molybdenum is an important alloying agent in steels, because it increases their toughness, corrosion resistance and weldability. About 80% of moly is used in the manufacturing of a variety of steels, such as stainless steels, structural steels, high-speed steels and tool steels.

Structural steels take up around 35% of total molybdenum consumption. It is used in structural steels due to its ability to enhance corrosion resistance, strength and durability. Corrosion resistant steels are used in a wide range of water based environment applications such as oil rigs, and oil and gas pipelines.

Stainless steels use around 25% of the molybdenum supply, which enhances the metal’s ability to strengthen and prevent corrosion. Typical applications include pharmaceutical and chemical mills, chemical transportation, nuclear power plant clean rooms, sanitation systems and many others.

High-speed steels consume 9% of the molybdenum processed, with superalloys accounting for 5%. Molybdenum added to these steels can improve their hardness and resistance to wear and toughness at high temperatures. High-speed steels are used to produce cutting tools and drills, and superalloys are used in the manufacture of turbochargers, jet engines, exhaust manifolds and power generation turbine blades.

Approximately 6% of the molybdenum produced every year goes into increasing the hardness, strength, temperature and pressure resistance of cast iron that is used to produce engine cylinder heads, engine blocks and vehicle exhaust manifolds.

The unique properties of molybdenum make it particularly suitable for applications requiring stability at high temperatures such as for aviation, lighting, welding, rocket engines, precision measurement equipment and many others.