High Temperature Applications for Tantalum include construction of vacuum furnaces, containers for liquid metals and vapours, thermocouple sheaths, boats and coils for product coating high temperature metals, resistance heaters, trays, thermowells, heat shields, glass production and protective coatings, crucibles manufacturing synthetic crystals such as diamonds and sapphires, crucibles for high temperature reactions.

The Bank of Kazakhstan uses the element for bimetallic coins where the center is tantalum and the ring is silver.

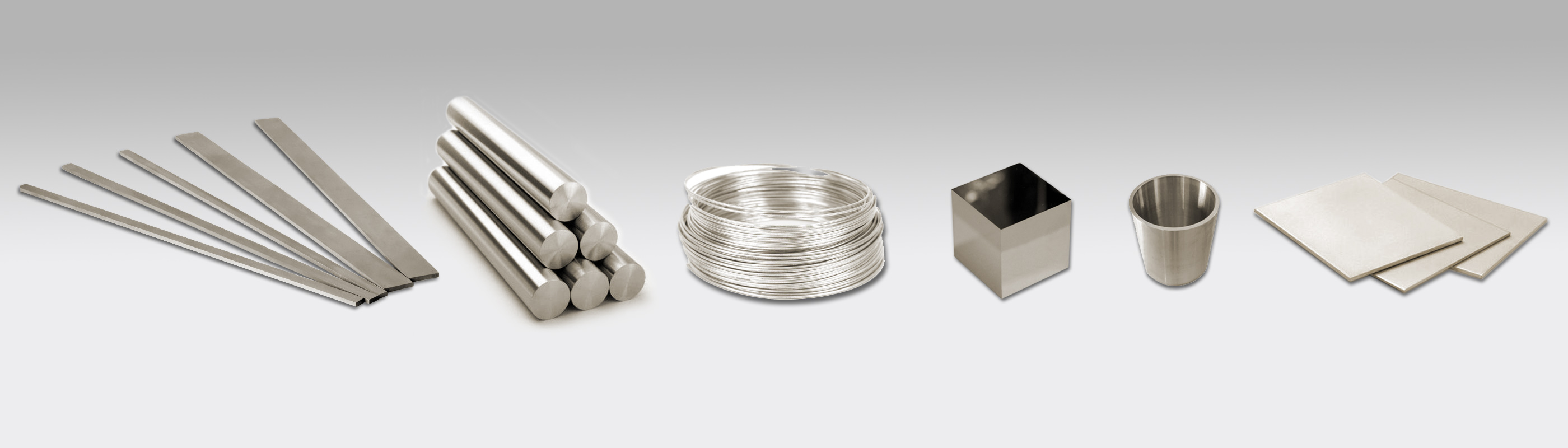

Tantalum alloys are utilised in laboratory equipment, weights for precise scales and balances, ball point pens, and tools that have to work at high temperatures and speeds.

Tantalums high melting point makes it suitable to be added to superalloys that are used for turbine blades of aircrafts, nuclear reactors, missile parts and gas turbines.

Tantalum’s high workability and weldability make it an ideal material for the construction of corrosion resistant Shell and Tube Heat Exchangers.